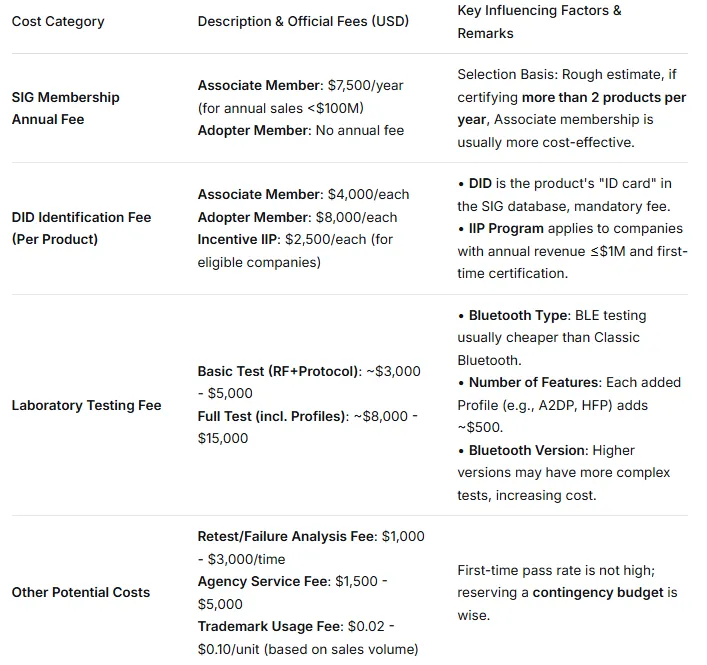

The cost of US BQB certification is not a fixed figure but consists of official fees charged by the Bluetooth SIG and testing service fees from third-party laboratories. The specific cost varies significantly based on your company's membership type, product design complexity, and the chosen certification path.

The table above lists the main cost items. Below are more specific interpretations and suggestions to help you better estimate and manage costs:

-Membership Fee vs. DID Fee Choice: You can roughly estimate a break-even point: if the number of products certified per year `N` satisfies `$4,000 * N + $7,500 < $8,000 * N`, i.e., when N ≥ 2, the total cost of an Associate membership is lower. For small businesses, check SIG's Incentive IIP Program, which significantly reduces the per-DID fee to $2,500, but note specific eligibility criteria (e.g., annual revenue not exceeding $1 million) and that this price is limited to 2 uses within 18 months.

-How to Control Testing Fees: Testing fees are the most variable part, primarily depending on:

·Certification Path: If your product uses a Bluetooth module that already has BQB certification (i.e., EPL Listing) and no modifications are made to the RF circuit, then usually no further full product testing is required, saving significant testing fees.

·Feature Complexity: The more Bluetooth "skills" (Profiles) a product supports, the more test cases are required, naturally increasing costs. Streamlining non-core Bluetooth functions during the product design phase is an effective way to control costs.

Practical Strategies for Optimizing BQB Certification Costs:

Overall, you can plan and control BQB certification costs more effectively through the following strategies:

1.Prefer Certified Modules:During the initial product design phase, prioritize using Bluetooth modules with full BQB certification. This is the most effective way to save costs and shorten the cycle.

2.Conduct Pre-testing: Before formal submission, conduct pre-testing (pre-scan) through a laboratory to identify and resolve potential RF or protocol compatibility issues in advance. This can greatly avoid additional costs from failure analysis and retesting due to formal test failures.

3.Plan Product Families: For product series with the same hardware platform but different models, apply for listing under one DID as a family, significantly reducing the average certification cost per product.

We hope this detailed cost explanation and strategic advice helps you better plan and execute your BQB certification project. If you can share more about the product type (e.g., headphones, speakers, or others) and expected annual shipment volume, a more precise cost analysis might be possible. BLUEASIA: +86 13534225140, will provide professional certification consulting services.

Related News