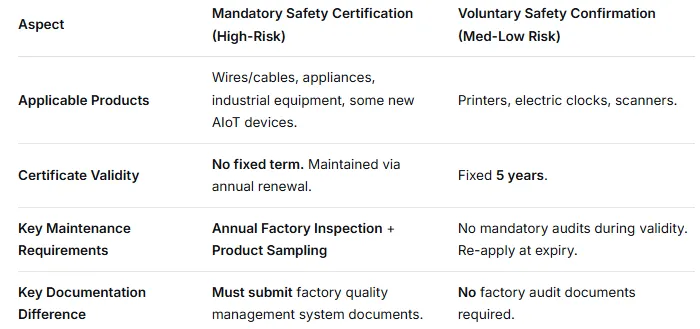

KC certification documentation and validity are not static. 2025 brings new rules and stricter oversight. The table below highlights core differences between the two main paths.

Beyond standard forms, schematics, and Korean manuals, note these 2025 points:

1.New Document Types: Some products now require a Cybersecurity Declaration of Conformity (for network-connected devices) and/or a Carbon Footprint Assessment Report (for some high-energy-consuming appliances).

2.Labeling & Manuals: The KC mark on the label must be ≥5mm tall with a clear certificate number. The Korean manual must contain explicit safety warnings and instructions.

3.Critical Component List: List parts like power supplies and batteries, and provide their KC or international CB certificates as evidence. E.g., a lithium battery inside the product must already have KC 62133 certification.

II. The Nature of KC Validity: Maintenance is Everything

A common misconception: obtaining the certificate is the finish line. Reality: "Certificate Validity = Continuous Compliance."

1.Mandatory Certification: No Expiry, But Annual Hurdles

No "expiration date," but validity requires passing the Annual Factory Inspection (cost: several thousand RMB). Additionally, the certifying body conducts at least one market or factory product sampling test annually. Failure in either leads to suspension/revocation.

2.Voluntary Confirmation: 5-Year Term, Then Reapply

Valid for 5 years from issuance. To continue sales after expiry, the product must be re-tested and a new certificate applied for.

3.Common Rule: Changes Must Be Reported

For both types, any change in design, critical components, or production site must be reported to the certifier for approval, potentially requiring supplementary certification. Unreported changes invalidate the certificate.

III. Professional Advice for Efficient Compliance

Two core recommendations:

1.Confirm Product Classification Early: Use the KATS website or consult an experienced certification body to ensure you take the correct path.

2.Take Annual Maintenance Extremely Seriously: Treat the annual audit and sampling as a mandatory "final exam." Conduct internal quality audits beforehand to ensure production consistency with the certified sample.

Planning for KC certification requires budgeting not just for initial costs, but also for annual maintenance audits, potential sampling costs, and compliance management overhead. If you can share your specific product type, more tailored advice on documentation and compliance can be provided. Contact BLUEASIA: +86 13534225140.

Related News