Australia's SAA certification is a vital safety certification for entering the Australian market. To help you prepare clearly and efficiently, below is a systematic overview of the certification process, timeline, and the latest policy dynamics as of 2025.

1.Preparation & Application:

This is the starting point for all work , focusing on preparing complete documents and samples.

·Core Documents: You need to prepare the application form (with detailed company and product info), technical file (like circuit diagrams, PCB layout, English manual, etc.), and a critical components list (noting existing certifications).

·Samples & Critical Components: Usually 2 to 4 finished product samples need to be prepared and sent to a NATA-accredited laboratory. Please pay special attention: If the product includes critical parts like power cords, plugs, or lamp holders, these components themselves must also provide valid SAA or CB certification; otherwise, the review cannot proceed.

2.Safety Testing:

This is the core part of certification. The laboratory conducts rigorous testing on samples according to Australian/New Zealand Standards (AS/NZS). Main items include:

·Electrical Safety Tests: Such as dielectric strength, insulation resistance, leakage current, earth continuity.

·Mechanical Safety Tests: Such as impact test, enclosure strength assessment.

·Environmental Tests: Such as temperature cycling, humidity test (simulating Australian tropical climate).

·Material Flammability Tests: Such as glow-wire test for plastic parts.

If testing fails, product modification and re-testing are required, incurring additional time and cost.

3.Review & Certification Issuance:

After successful testing, the certification body conducts a review. For some high-risk products (e.g., medical devices) or first-time applicants, a factory audit might be required to inspect the production line's quality control system.

After passing the review, the certification body issues the SAA Certificate of Suitability. This certificate has a maximum validity of 5 years (for some high-risk products, it may be shortened to 1-3 years).

4.RCM Registration (Key Step for Market Access):

Please note: Obtaining the SAA certificate does not mean the process is over. Since 2016, Australia has consolidated safety certification (SAA) and EMC certification (C-Tick) into the RCM mark (Regulatory Compliance Mark).

Therefore, after obtaining the SAA certificate, you must upload the SAA certificate together with the Electromagnetic Compatibility (EMC) report (like C-Tick) to the official ERAC database to complete RCM mark registration. Only products bearing the RCM mark can be legally sold in the Australian market.

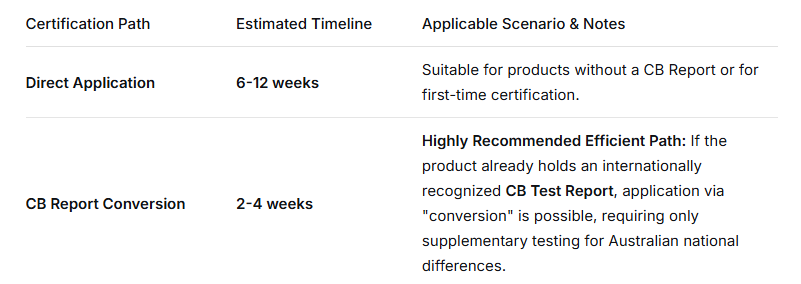

Australia SAA Safety Certification Timeline & Optimization Path:

The certification timeline is affected by product complexity, lab scheduling, and the number of modification rounds. There are two main paths:

Important Reminders & New Regulation Interpretation:

Besides the regular process, the following latest dynamics and practical advice are crucial for your successful certification:

-2025 Localization Requirements & Standard Updates:

·Products must meet Australian localization requirements, including voltage (230V/50Hz) and plug type (must comply with AS/NZS 3112 for the flat 3-pin plug).

·Standards for some products have been updated. When preparing for certification, be sure to confirm the latest applicable standard version with the laboratory or certification body.

-Non-Compliance Risk Warning: Selling products in Australia without mandatory certification or correct RCM marking will result in product seizure, significant fines (up to over USD 200,000), and forced removal from e-commerce platforms like Amazon.

We hope this overview combining the latest 2025 Australian SAA Safety Certification process and timeline provides clear guidance. If you have more detailed questions about certification for specific product categories (e.g., luminaires, appliances), BLUEASIA: +86 13534225140, will provide you with professional certification consulting services!

Related News