Timeliness Statement: This document is based on the latest March 2025 policy from the Korea Agency for Technology and Strategy (KATS). Relevant regulations are subject to dynamic adjustments. Enterprises are advised to confirm the latest requirements with official authorized bodies before initiating certification.

Cross-border exporters of electrical and electronic products to South Korea will notice significant changes in the 2025 KC mandatory certification compliance requirements: new cybersecurity standards for IoT devices, extended factory audit scheduling cycles, and simultaneous upgrades to energy efficiency and environmental protection standards. Combining KATS' official updates with Blue Asia Testing's frontline data, this guide integrates regulatory standards with practical implementation to help you avoid time and cost pitfalls.

South Korea has further refined the scope of “high-risk products” subject to mandatory certification in 2025. Not all electrical and electronic products require this process, categorized into three groups:

Basic Mandatory Category: Major appliances like refrigerators and washing machines; power adapters and cables with output power exceeding 100W.

·Newly Added High-Risk Category for 2025: Smart appliances with WiFi/Bluetooth (e.g., networked air conditioners, smart rice cookers); industrial PLC control modules; commercial wireless charging devices.

· Special Mandatory Category: Lithium batteries (must comply with KC 62133 safety standards), wireless communication devices (requires KCC RF compliance certification in addition to KC safety certification).

A critical reminder: All network-enabled devices, regardless of power rating, must meet the KN18031 cybersecurity standard by 2025. This is the core new regulation this year, which we will break down in detail later.

II. Full Process for KC Mandatory Certification in 2025:

1.Preliminary Preparation: 3 Common Pitfalls (with Real-Life Examples)

Preliminary preparation most easily delays the overall timeline. Several critical details must be closely monitored under the 2025 requirements:

·Correct Product Classification: Smart plugs eligible for voluntary certification in 2024 will be reclassified as mandatory in 2025 due to networking capabilities, requiring additional factory audits. One client misclassified their product, initially applying for voluntary certification and incurring a 10-day delay when supplementing materials mid-process. We recommend verifying the certification type by entering the product's HS code on the KATS website—this is more reliable than relying on experience.

·Technical documentation must be “entirely in Korean + precisely annotated”: Starting in 2025, the Bill of Materials (BOM) must list the KC certification number for each critical component (e.g., the certificate code for the power supply chip). Circuit diagrams require separate annotation for 220V/60Hz voltage adaptation modules. Last year, a client's document review stalled for one week due to an omission of capacitor certification numbers in the BOM, requiring resubmission with corrections.

·Mandatory qualifications for Korean authorized representatives: Starting in 2025, agents must be legal entities registered with Korean notary offices—individual agents are prohibited. The agent's full name, phone number, and address must be printed on product labels.

2.Application and Testing: Cybersecurity Testing as a Core New Requirement

The most significant change in the 2025 testing phase is the mandatory addition of penetration testing for IoT devices. The specific process is as follows:

-Application Submission: Submit the application form to the authorized Korean government agency, attaching the registered agent certification. The application fee has increased by 5% compared to 2024, with the market range typically between $200-300 (slightly variable across agencies).

-Sample Requirements: Provide at least 2 finished products identical to the mass-production version. Engineering samples are not accepted under any circumstances. A previous client submitted an engineering sample (with PCB layout differing from production) and incurred an additional 3 weeks for retooling and resubmission, disrupting their shipment schedule.

-Test Items (New 2025 items highlighted in red):

·Basic Safety Testing: Per KN 60335 standard, test 2500V insulation withstand voltage, leakage current, and temperature rise;

·EMC Testing: Radiated Emissions (RE), Conducted Emissions (CE). Wireless devices require additional Bluetooth/WiFi band compliance testing;

·KN18031 Cybersecurity Testing: Simulates hacker attacks to detect device vulnerabilities (e.g., potential control compromise). This report requires separate submission for review.

Cost-saving acceleration tip: If the product already holds a CB certification report, most safety tests can be exempted. Only “Korea-specific tests” (e.g., 220V/60Hz voltage adaptation, Korean warning label compliance) need to be supplemented, saving 2-3 weeks compared to full testing. More crucially, leveraging CB to KC conversion can directly shorten the overall testing cycle to 2-3 weeks—a core acceleration strategy for many companies this year.

3.Factory Audit: 2025 Fees & New Appointment Requirements

Factory audits are required only for mandatory certification products. Specific adjustments for 2025 audits are outlined below based on practical experience:

· Core Focus: Verifying “Production Consistency”—ensuring production line components match the Bill of Materials (BOM). Last year, one factory failed inspection due to unauthorized replacement of uncertified capacitors, incurring an extra month for rectification and re-inspection.

· Fees and Timeline: Domestic factory audits take 1-2 days, with standard market fees ranging from $565-$640 (some agencies may charge $600-$680 for value-added services; confirm in advance). Overseas factories (e.g., China-based) require 1-2 months advance notice to schedule auditors. Travel expenses are reimbursed at cost, typically incurring an additional $1,000-$1,500.

·Pre-inspection Recommendations: Conduct an internal pre-inspection one week prior, focusing on verifying the completeness of IQC incoming material inspection records. During a client's pre-inspection, we discovered three months of missing quality inspection records; timely supplementation ensured successful certification.

4.Certification & Compliance: Distinguish Certificate Validity by Type

For 2025 KC certificates, clearly differentiate validity periods by certification type to avoid confusion:

· Mandatory Safety Certification: No fixed validity period, but requires annual maintenance (including factory audits and product sampling). Failure to complete maintenance on time will invalidate the certificate, with reactivation taking 1 month.

· Voluntary Safety Confirmation: Certificate validity is 5 years. Renewal can be applied for 3 months prior to expiration without repeating full testing.

Additionally, product labels must display three critical details: the KC mark (height ≥5mm, must be clear), the certificate number (format: “KC:XXXX-XXXXX”), and complete details of the Korean agent. Omission of any element may result in customs detention. One client omitted the agent's phone number, forcing them to return goods upon arrival and reapply labels—adding two weeks to the process.

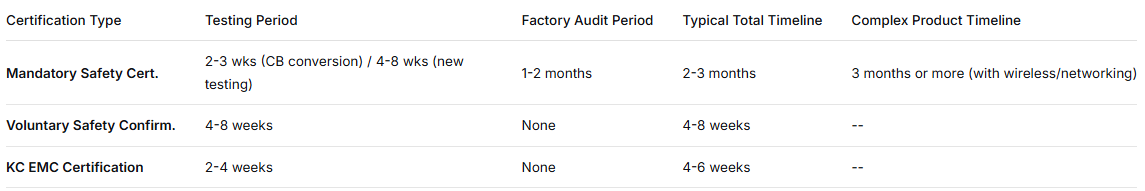

III. Detailed 2025 KC Certification Timelines:

Many companies inquire about “certification lead times.” Based on 2025 operational data, product-specific timelines vary significantly. Key findings are summarized below:

Three “Time Killers” Affecting Duration:

1.Product Complexity: Smart appliances with network connectivity (e.g., refrigerators with displays) require simultaneous cybersecurity and EMC testing, extending the timeline by 30% compared to standard appliances. While conventional refrigerators take 2-3 months for certification, smart models may require 3-4 months.

2.Testing Corrections: Failure in insulation withstand voltage testing (e.g., insulation breakdown) necessitates 1-2 weeks for corrective actions, followed by another week for retesting. Recommend conducting pre-testing at a CNAS-accredited lab domestically to avoid such delays.

3.Document Translation: Non-professional translations of Korean technical documents often contain errors (e.g., inaccurate technical terminology), causing at least 1 week of delay due to review rejections and re-translation. Engage translation agencies with Korean certification experience.

2 Key Practical Acceleration Techniques:

1.Prepare Korean technical documents (especially BOMs and label artwork) 3 months in advance to avoid post-submission material supplementation;

2.For IoT devices, conduct cybersecurity pre-testing at domestic labs (e.g., Blue Asia Testing) before submitting to Korea, saving 2-3 weeks.

KC certification hinges on “detailed compliance.” Despite numerous 2025 regulations, completing mandatory certification within 2-3 months is achievable through advance preparation and strategic use of acceleration methods like CB scheme transfers. For product-specific certification inquiries, contact Blue Asia Technical Support at +86 13534225140 for professional consultation.

相关新闻