To secure a foothold in the European Union market, that small "CE" mark on your product is your indispensable passport. Among the various directives that constitute CE certification, the Electromagnetic Compatibility (EMC) Directive is a critical hurdle that almost all electrically powered products must clear.

It is no longer an optional "technical test" but a "lifeline" directly related to whether your products can clear customs, be sold legally, and even protect your brand's reputation. Every year, a significant number of Chinese-manufactured goods face notifications, recalls, and substantial financial losses from EU market surveillance authorities due to EMC issues. This article will deconstruct the latest landscape of CE EMC certification, highlight key dynamics to watch in 2025, and provide a proven strategy for efficient compliance.

Many simplify EMC to "the product doesn't interfere with others and isn't susceptible to interference from others." While technically accurate, this view falls short from commercial and compliance perspectives.

The EU EMC Directive (2014/30/EU) is a legal requirement. Affixing the CE mark signifies the manufacturer's legally binding declaration to EU authorities and consumers that the product complies with all applicable EU regulations, including EMC.

Its core value manifests in three dimensions:

1.Market Access License: Without the CE mark (and its supporting compliance evidence), products risk detention or refusal at EU customs.

2.Risk Firewall: Compliant products significantly reduce the risk of causing other device malfunctions or even safety incidents due to electromagnetic interference, thereby avoiding massive liability claims and brand crises.

3.Quality Trust Badge: For consumers and professional buyers, the CE mark is a visible indicator of a product that has undergone rigorous assessment for safety and reliability.

II. 2025 Trends: Evolving Standards & Stricter Oversight

Regulations and standards are not static. To stay ahead in 2025 and beyond, you must monitor these developments:

1.Ongoing Harmonization of Standards: EU EN standards are continuously updated in alignment with international standards from bodies like the International Electrotechnical Commission (IEC). For instance, standards like EN 55032 (emission standard for multimedia equipment) and the EN 61000-4 series (immunity standards) are periodically revised. While the directive number (2014/30/EU) remains unchanged, when referenced standard versions are updated, old versions enter a transition period before being phased out. Best Practice: Confirm the latest applicable standard version with your certification body at the project outset.

2.Deeper Scrutiny for Complex & Wireless Products: For highly integrated smart appliances and products with Wi-Fi, Bluetooth, etc., simple pass/fail testing is insufficient. Notified Bodies now scrutinize technical files more deeply, focusing on:

-Risk Assessment Depth: The thoroughness of EMC risk identification, evaluation, and control measures in your technical documentation.

-Software's Role: Assessment of software's function in error recovery or immunity, if applicable.

-RF & EMC Intersection: Wireless products must also comply with the Radio Equipment Directive (RED). Internal EMC interference between RF modules and other circuits is a key testing focus.

3.Enhanced Market Surveillance: Documentation is King: EU national surveillance authorities are conducting more frequent checks. They not only inspect the CE mark but can demand the complete Technical Documentation from the manufacturer or importer within a short timeframe (often 10 days). Missing or non-compliant files can lead to product recalls and penalties, even if the product itself is sound. Therefore, establishing and maintaining a complete, standardized technical file library is as crucial as passing the tests.

III. The Four-Step CE EMC Certification Core Process

Step 1: Pre-application & Gap Analysis (Duration: 1-2 Weeks)

This critical, often overlooked stage determines project efficiency and cost.

-Product Classification & Standard Mapping: Identify your product category (household appliance, IT equipment, industrial device, etc.), which dictates applicable core standards (e.g., EN 55014-1, EN 55032).

-Pre-compliance Testing (Highly Recommended): Submit samples to a third-party lab for pre-scanning before formal testing. This proactively identifies common issues like radiated (RE) or conducted (CE) emission failures at a fraction of the cost of post-failure redesign and retesting.

-Initiate Technical File Preparation: Start drafting your technical documentation framework immediately; don't wait until testing is complete.

Step 2: Formal Testing & Rectification (Duration: 2-6 Weeks)

This is the technical tackle tough challenges stage. Products undergo full EMI (Interference) and EMS (Immunity) testing at an accredited lab.

-EMI Tests: Ensure your product "doesn't interfere."

·Radiated Emission (RE): Measures electromagnetic noise propagated through space.

·Conducted Emission (CE): Measures electromagnetic noise conducted through power cables.

-EMS Tests: Ensure your product "isn't susceptible."

·Electrostatic Discharge (ESD), Radiated Susceptibility (RS), Electrical Fast Transient/Burst (EFT/B), Surge, Voltage Dips and Interruptions.

·Addressing Test Failures: For non-compliances, lab engineers suggest rectifications like PCB layout adjustments, adding filter circuits, improving shielding, or modifying grounding. Affected items require retesting post-modification.

Step 3: Technical File Compilation & Review (Duration: 1-2 Weeks)

The test report is just one part. A compliant Technical File must include:

1. Product description and specifications.

2. Draft EU Declaration of Conformity (DoC) – the core legal document.

3. Complete technical drawings (circuit diagrams, PCB layouts, mechanical drawings).

4. Critical Component List (BOM) with compliance evidence (e.g., certificates).

5. Detailed test reports.

6. User manual (in English or target market language).

7. EMC Risk Assessment Report.

The Notified Body reviews these for completeness and consistency.

Step 4: Issuance & Marking

Upon approval, the Notified Body issues certificates, the manufacturer signs the formal DoC, and affixes the CE mark to the product. The mark must be clear, permanent, and at least 5mm in height.

IV. Cost & Timeline Management

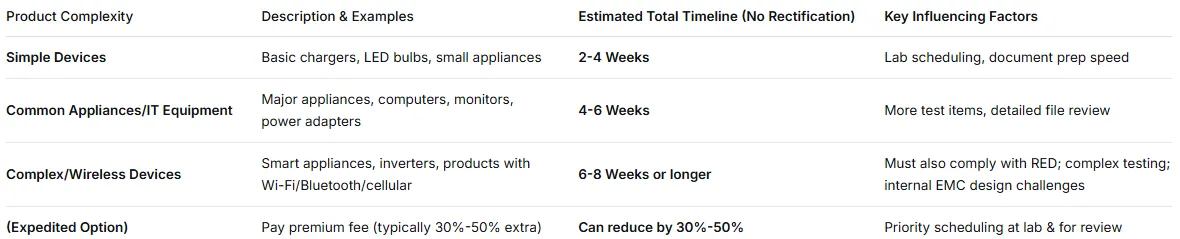

Costs and timelines vary significantly based on product complexity and first-pass success rate.

Cost Breakdown:

-Testing Fees: The major cost (60%-80%), ranging from a few thousand RMB for simple items to tens of thousands for complex/industrial/wireless devices.

-Service/Certification Fees: For file review and certificate issuance by the Notified Body.

-Rectification & Retest Fees: An unpredictable potential overrun, which pre-compliance testing helps mitigate.

-Hidden Costs: Internal labor, sample preparation, shipping.

Timeline Overview & Acceleration Tips:

At its core, CE EMC certification is a rigorous product risk management system. In today's competitive global market, compliance is no longer just a cost but a fundamental component of "competitiveness" and "resilience."

BLUEASIA Tech: +86 13534225140 provides professional certification consulting services.

Related News